Full automatic PET bottle blowing machine

Maintenance service solutions for customers assigned: kinglight professionals throughout the year, the professional personnel according to the manufacturer's production plan of mechanical equipment status, and help the maintenance team comply with the decision of the construction operation, this is an ideal means of large maintenance operation arrangement, our customers can be used between two a complete production cycle.

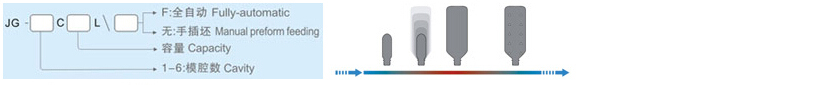

Naming rules for bottle blowing machines:

Automatic bottle blank input and forming bottle output system.

The whole machine adopts the super standard anti vibration overall structure design, in the high speed operation of the machine, the vibration to the minimum degree, to ensure that the use of parts is not due to the vibration of the machine and affect the service life.

And the whole machine adopts modular assembly method, which is greatly convenient for the local modification of the equipment in the process of use in the future.

In order to ensure the rate of finished products, the oven is in a very important position in measuring the performance of the machine. The machine is used in the oven structure of the current international most advanced infrared radiation heating energy saving technology. Temperature control adopts automatic negative feedback and closed loop control mode.

Automation control using the international high-end brand of the whole computer system, analog input module to complete the heating temperature, the surface temperature of the preform collection, measurement.

The man-machine industry shows the current production dynamics, can be switched on line, parameter correction and production statistics, with automatic detection, diagnosis function.

And can store 7 groups or more bottle blow molding process parameters, the replacement of different products and the preform, can be retrieved directly from the computer without the need to re adjust the data.

Using the international high-end brand pneumatic components, high flow exhaust system to ensure the high-speed operation of the machine.

In order to save the gas source, can choose the high pressure blow bottle exhaust gas recovery system, only this one can save the 10-15% gas source.